- Overview

- Product Name

- Product Specification

- Detailed Photos

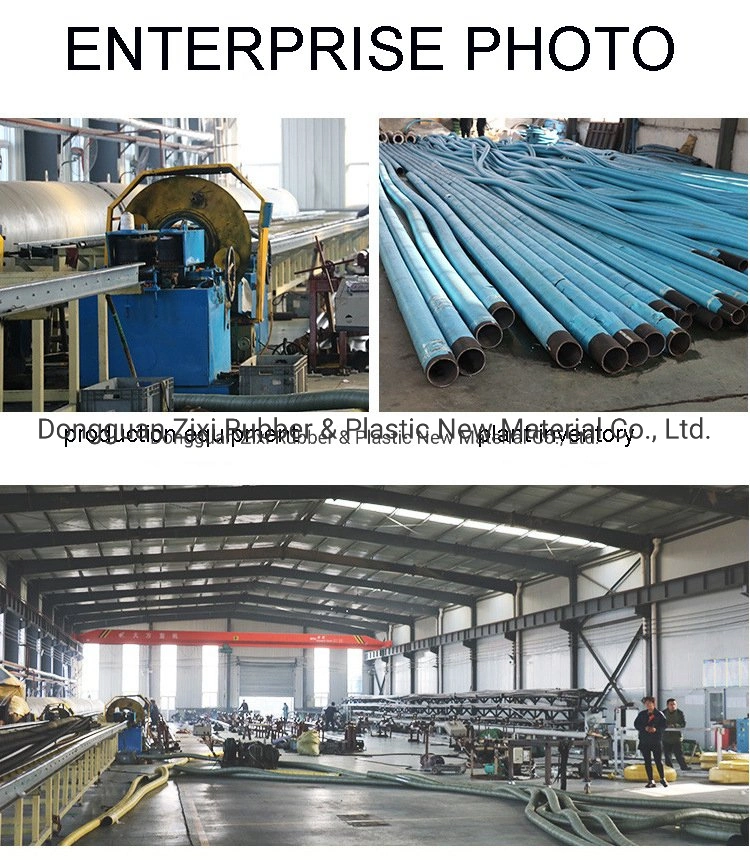

- Production Workshop

- Product Application

- International Experiance

- Certifications

- Our Advantages

Basic Info.

Product Description

High Pressure Steel Wire Braided Hose

| High pressure steel wire braided hose: |

| 1. Product structure |

| The structure of the steel wire braided hose is composed of a liquid-resistant synthetic rubber inner rubber layer, a middle rubber layer, a one or two or three layer of steel wire braided reinforcing layer, and a synthetic rubber outer rubber layer with excellent weather resistance. |

| 2. Product use |

| Steel wire reinforced hydraulic rubber hose is mainly used for mine hydraulic support, oilfield mining, suitable for engineering construction, lifting and transportation, metallurgical forging, mining equipment, ships, injection molding machinery, agricultural machinery, various machine tools and various industries Transportation of petroleum-based (such as mineral oil, soluble oil, hydraulic oil, fuel oil, lubricating oil) liquid, water-based liquid (such as emulsion, oil-water emulsion, water), water-based liquid (such as emulsion, oil-water emulsion, water), For gas, etc. and liquid transmission. |

| Note: The steel wire braided hose of our company is designed and manufactured according to the GB/T3683-1992 standard, and can be produced according to the requirements of ISO/DIS1436-1985, DIN20022 and SAE100R1AT, SAE100R2AT standard hoses, this standard is not suitable for castor oil-based and grease-based liquids. |

| 3. Working temperature |

| oil: -40ºC-+100ºC, air -30ºC-+50ºC |

| water: emulsion below +80ºC |

| 4. Product Features |

| (1) The hose is made of special synthetic rubber, which has excellent oil resistance, heat resistance and aging resistance. |

| (2) The hose has high bearing pressure and excellent pulse performance. |

| (3) The tube body is tightly combined, soft to use, and less deformed under pressure. |

| (4) The hose has excellent bending resistance and fatigue resistance. |

| (5) The length of the steel wire braided hose is large, the fixed length above Φ32 is 20 meters, and the length below Φ25 can reach ten meters or even more than 100 meters. |

| Product Description |

| 1. Structure |

| The inner and outer rubber layers of the cloth steam hose are made of synthetic rubber with excellent heat resistance, and the middle pure cotton canvas reinforcement layer. The tube body is soft, light, flexible, and heat resistant. |

| 2. Purpose |

| It is suitable for conveying saturated steam or superheated water not higher than 150ºC. |

| 3. Features |

| The rubber layer has good heat resistance, and the burst pressure of the rubber tube is not less than 10 times of the working pressure. |

| technical parameters of single-layer steel wire braided hose | |||||||||||

| hose size | the inside diameter | diameter of steel wire layer(mm) | outer diameter | work pressure | test pressure | burst pressure | minimum bending radius(mm) | reference weight(kg/m) | |||

| MPA | Psi | MPa | Psi | MPa | Psi | ||||||

| 1-5-21 | 4.5-5.5 | 9.5±0.6 | 14±0.8 | 21 | 3043 | 31.5 | 4564 | 63 | 9129 | 90 | 0.25 |

| 1-6-20 | 5.5-6.5 | 11.7±0.6 | 16±0.8 | 20 | 2898 | 30 | 4347 | 60 | 8694 | 100 | 0.34 |

| 1-8-17.5 | 7.5-8.5 | 13.7±0.6 | 18±0.8 | 17.5 | 2536 | 26.25 | 3804 | 52.5 | 7607 | 115 | 0.41 |

| 1-10-16 | 10±0.5 | 15.7±0.6 | 20±0.8 | 16 | 2318 | 24 | 3478 | 48 | 6955 | 130 | 0.47 |

| 1-13-14 | 13±0.5 | 19.7±0.6 | 24±1.0 | 14 | 2028 | 21 | 3043 | 42 | 6086 | 180 | 0.70 |

| 1-16-12 | 16±0.5 | 22.7±0.8 | 27±1.0 | 12 | 1739 | 18 | 2608 | 36 | 5216 | 205 | 0.84 |

| 1-19-10 | 19±0.5 | 25.7±0.8 | 30±1.0 | 10 | 1449 | 15 | 2174 | 30 | 4347 | 240 | 0.95 |

| 1-22-9 | 22±0.5 | 28.7±0.8 | 33±1.0 | 9 | 1304 | 13.5 | 1956 | 27 | 3912 | 280 | 1.09 |

| 1-25-8 | 25±0.5 | 32.2±0.8 | 37±1.0 | 8 | 1159 | 12 | 1739 | 24 | 3478 | 300 | 1.38 |

| 1-32-6 | 32±0.5 | 39.2±0.8 | 44±1.2 | 6 | 869 | 9 | 1304 | 18 | 2608 | 420 | 1.80 |

| 1-38-5 | 38±0.7 | 45.2±0.8 | 50±1.2 | 5 | 725 | 7.5 | 1087 | 15 | 2174 | 500 | 1.38 |

| 1-51-4 | 51±1.0 | 58.2±0.8 | 63±1.5 | 4 | 579 | 6 | 8694 | 12 | 1739 | 630 | 1.80 |

| 1-64-2.5 | 64±1.0 | 71±0.8 | 75±1.5 | 2.5 | 362 | 3.75 | 543 | 7.5 | 1087 | 770 | 4.00 |

| 1-76-1.5 | 76±1.0 | 84±0.8 | 88±1.5 | 1.5 | 217 | 2.25 | 326 | 4.5 | 652 | 930 | 5.50 |

| 1-89-1 | 89±1.0 | 99±0.8 | 103±1.5 | 1 | 144.9 | 1.5 | 217 | 3 | 435 | 1100 | 7.60 |

| 1-102-1 | 102±1.0 | 111±0.8 | 115±1.5 | 0.8 | 116 | 1.2 | 174 | 2.4 | 348 | 1250 | 9.00 |

| technical parameters of double-layer steel wire braided hose | |||||||||||

| hose size | the inside diameter | diameter of steel wire layer(mm) | outer diameter | work pressure | test pressure | burst pressure | minimum bending radius(mm) | reference weight(kg/m) | |||

| MPA | Psi | MPa | Psi | MPa | Psi | ||||||

| 2-5-60 | 5±0.5 | 11.2±0.6 | 15±0.8 | 60 | 8694 | 90 | 13041 | 150 | 21735 | 90 | 0.40 |

| 2-6-60 | 6±0.5 | 13.5±0.6 | 18±0.8 | 60 | 8694 | 90 | 13041 | 150 | 21735 | 100 | 0.45 |

| 2-8-50 | 8±0.5 | 15.5±0.6 | 20±0.8 | 50 | 7245 | 75 | 10868 | 125 | 18113 | 115 | 0.62 |

| 2-10-40 | 10±0.5 | 17.5±0.6 | 22±0.8 | 40 | 5796 | 60 | 8694 | 100 | 14490 | 130 | 0.71 |

| 2-10-53 | 10±0.5 | 16.5±0.6 | 24±0.8 | 53 | 7680 | 79.5 | 11520 | 132 | 19127 | 130 | 0.71 |

| 2-13-30 | 13±0.5 | 21.5±0.8 | 26±1.0 | 30 | 4347 | 45 | 6521 | 90 | 13041 | 180 | 0.93 |

| 2-16-21 | 16±0.5 | 24.5±0.8 | 29±1.0 | 21 | 3043 | 31.5 | 4564 | 63 | 9129 | 205 | 1.00 |

| 2-16-34 | 16±0.5 | 24.5±0.8 | 30±1.0 | 34 | 4929 | 51 | 7390 | 85 | 12317 | 205 | 1.23 |

| 2-19-18 | 19±0.5 | 27.5±0.8 | 32±1.0 | 18 | 2608 | 27 | 3912 | 54 | 7825 | 240 | 1.23 |

| 2-19-34 | 19±0.5 | 27.5±0.8 | 32±1.0 | 34 | 4926 | 51 | 7390 | 85 | 12317 | 240 | 1.38 |

| 2-22-16 | 22±0.5 | 30.5±0.8 | 35±1.0 | 16 | 2318 | 24 | 3478 | 48 | 6955 | 280 | 1.54 |

| 2-25-14 | 25±0.5 | 34±0.8 | 39±1.0 | 14 | 2029 | 21 | 3043 | 42 | 6086 | 300 | 1.54 |

| 2-32-11 | 32±0.5 | 41±0.8 | 40±1.2 | 11 | 1594 | 16.5 | 2391 | 33 | 4782 | 420 | 1.82 |

| 2-38-10 | 38±0.7 | 47±0.8 | 52±1.2 | 10 | 1449 | 15 | 2174 | 30 | 4347 | 500 | 2.44 |

| 2-51-8 | 51±1 | 60±0.8 | 65±1.5 | 8 | 1159 | 12 | 1789 | 24 | 3478 | 630 | 3.18 |

| 2-64-5 | 64±1 | 74±1 | 79±1.5 | 5 | 725 | 7.5 | 1087 | 15 | 2174 | 790 | 3.74 |

| 2-76-4 | 76±1 | 86±1 | 92±1.5 | 4 | 580 | 6 | 895 | 12 | 1789 | 920 | 4.77 |

| 2-89-3 | 89±1 | 99±1 | 106±1.5 | 3.5 | 507 | 5.25 | 761 | 10.5 | 1521 | 1060 | 5.73 |

| 2-102-5 | 102±1 | 112±1 | 118±1.5 | 5 | 435 | 4.5 | 652 | 9 | 1304 | 1200 | 6.16 |

| 2-127-4 | 137±1 | 137±1 | 143±1.5 | 4 | 290 | 3 | 448 | 6 | 869 | 1450 | 7.32 |

1.Q: Are you manufacture or trade company?

A:We are manufacture factory

2.Q: How can I get the samples?

A:If you need some samples to test, we can make as per your request .The transportation freight of samples and our samples cost wil be on the buyer, while the samples cost can be refundable after you place the order if the amount meets our requirement.

3.Q:How much the transportation freight of samples?

A:The freight depends on the weight and packing size and your area.

4.Q:How long can I expect to get the sample?

A:The samples will be ready for delivery within 7 days. The samples will be sent via express and arrive in 4-7 days.

5.Q:Is OEM, ODM accepted?

A:Yes,sure,we can print your logo.

6.Q:How to order?

A: Please send us your purchase order by Email or you can ask us to send you a invoice for your order. We need to know the following information for your order:

1) Product information-Quantity, Specification (Size, Material, Technological and Packing requirements etc.)

2) Delivery time required.

3) Shipping information-Company name, Street address, Phone &Fax number, Destination sea port.

4) Forwarder's contact details if there's any in China(if have).

Contact Person

Celina Du

Dongguan Zixi Rubber & Plastic New Material Co., Ltd