- Overview

- Product Parameters

- Certifications

- Company Profile

- FAQ

Basic Info.

Product Description

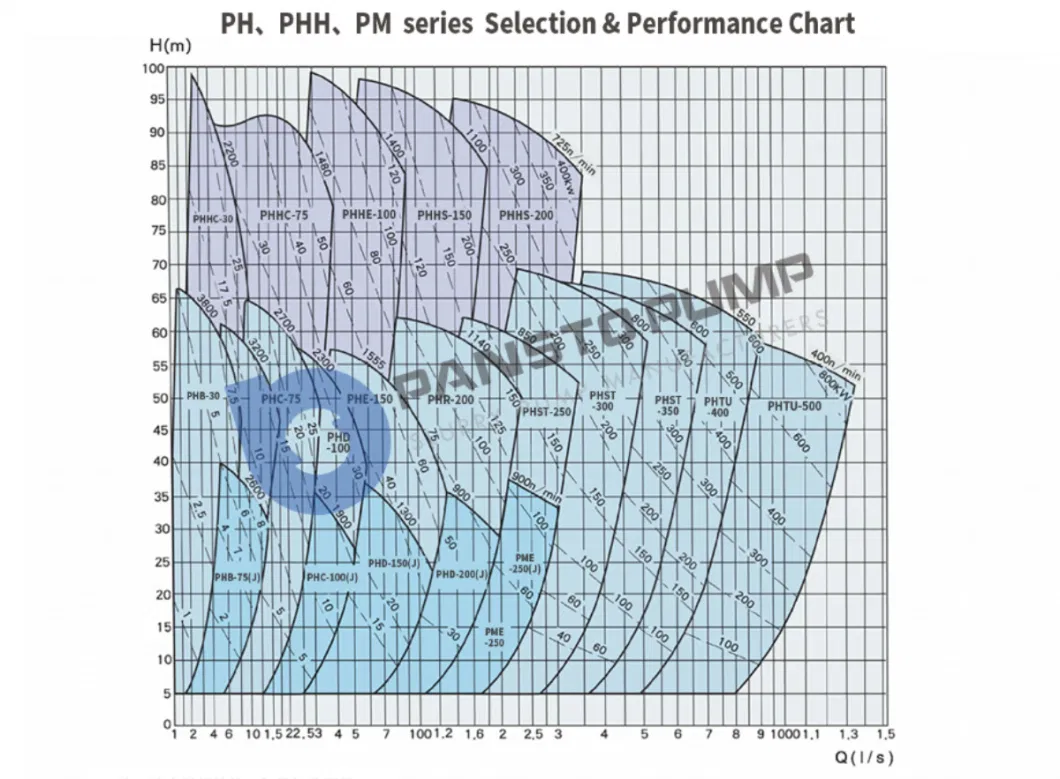

PH Series Slurry Pump

Product Introduction

This series of slurry pump is a cantilever centrifugal double shell slurry pump, double pump shell pump body pump cover with a replaceable wear metal liner or natural rubber lining,1. It is suitable for transporting abrasive or corrosive slag slurry. It is widely used in metallurgy, mining, petroleum, chemical industry, coal, electric power, transportation, river dredging, building materials and municipal engineering.

PH(J) and PHH pumps can also be called heavy slurry pumps. Because this type of pump has thick wear parts and heavy bracket, it is suitable for conveying strong abrasion, high concentration slag slurry or low concentration high lift slag slurry. It can be used in series at multiple levels within the maximum allowable working pressure range of the pump. HH pump is suitable for conveying low concentration high head slag slurry or high concentration low abrasive high head pump.

Detailed Photos

Technical Parameters

| Model | Distribution power P(KW) | Clear water performance | |||||

| Flow Q(m³/h) | Head H(m) | Rotational speed n(r/min) | Efficiency η% | Cavitation allowance NPSH(m) | Weight (Kg) | ||

| PHB-40 | 2.2-15 | 3.6-20 | 5-68 | 1200-3800 | 40 | 2-4 | 91 |

| PHB-50 | 2.2-15 | 7-48 | 7-62 | 1200-3200 | 45 | 3.5-8 | 118 |

| PHC-75 | 4-30 | 21-86 | 12-65 | 1300-2700 | 55 | 4-6 | 191 |

| PHC-100 | 5.5-30 | 50-150 | 9-45 | 1000-2000 | 71 | 4-6 | 263 |

| PHD-100 | 7.5-60 | 68-160 | 10-52 | 1000-2200 | 71 | 4-6 | 363 |

| PHD-150 | 15-60 | 72-360 | 12-56 | 800-1550 | 65 | 5-8 | 626 |

| PHE-150 | 22-120 | 93-385 | 12-63 | 800-1600 | 65 | 5-8 | 728 |

| PHE-200 | 18.5-120 | 360-820 | 10-61 | 500-1100 | 72 | 2-9 | 1473 |

| PHR-200 | 110-300 | 360-820 | 10-61 | 500-1140 | 72 | 2-9 | 1836 |

| PHST-250 | 45-560 | 630-1300 | 11-60 | 400-850 | 71 | 4-10 | 3750 |

| PHST-300 | 55-560 | 800-1900 | 7-58 | 350-730 | 82 | 6 | 4318 |

| PHST-350 | 75-560 | 1200-2600 | 13-60 | 300-600 | 77 | 3-10 | 4609 |

| PHTU-400 | 160-1200 | 1368-3000 | 11-60 | 250-550 | 79 | 4-10 | 10000 |

Product Diagram

Certificates

Company Profile

At present our products involve more than a dozen series and more than 100 varleties. The main products are horizontal slurry pumps, vertical slurry pumps, rubber lined pumps, gravel pumps, froth pumps, desulfurization pumps, filter press feed pumps, dredge pumps, sewage pumps, submersible slurry pumps and spare parts. The compamy has a number of high-quality, high-level and experienced technical and management elites. The material can be adjusted according to the actual working conditions of customers, So as to improve the wear resistance and corrosion resistance of the pump and greatly prolong the service life of the pump. Our products are widely used in beneficiation, metallurgy coal,electric power, petroleum, chemical industry, sand excavation, urban sewage, environmental protection and other industries.

Workshop

WorksWorkshophop

Worksho

Workshop

Product Accessories

Application

Product Transportation

FAQ

Pansot mainly produce horizontal slurry pumps, vertical slurry pumps, rubber lined pumps, gravel sand pumps, froth pumps, desulfurization pumps, filter press feed pumps, dredge pumps, sewage pumps, submersible slurry pumps and spare parts.

2. Is Pansto direct factory or trader?

Yes, Pansto is direct Slurry Pump Manufacturer with Export and Import License, having its own foundry workshop, Machining Workshop, Heat treatment equipment and Assembly workshop, also advanced quality inspection equipment.

3. Can you provide OEM, ODM service?

Yes. OEM Service is an important part of our business. Pansto Pump accept OEM business as samples or drawings of all kinds of pumps and casting spare parts. And more we offer ODM service too.

4. What is your warranty period?

We provide one year of unconditional warranty on our products for the manufacturing defects.

5. What about delivery time?

Normally our production time is within two weeks. Please confirm before order.

6. The Min MQQ?

The MQQ is one pcs pump or spare parts.

Welcome to Contact Us!